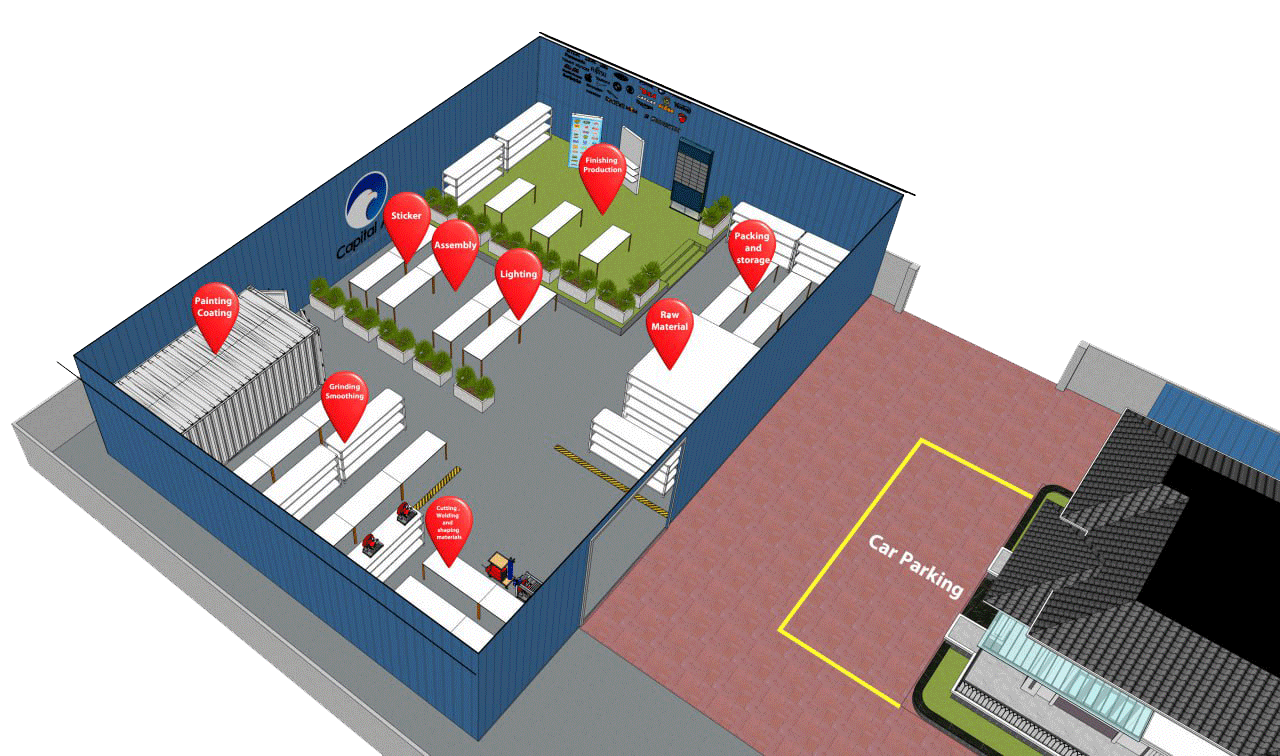

At Capital Arts, we take pride in offering complete signage production solutions under one roof — from design to delivery. Our goal is simple: transform your ideas into high-quality, durable, and visually striking signs.

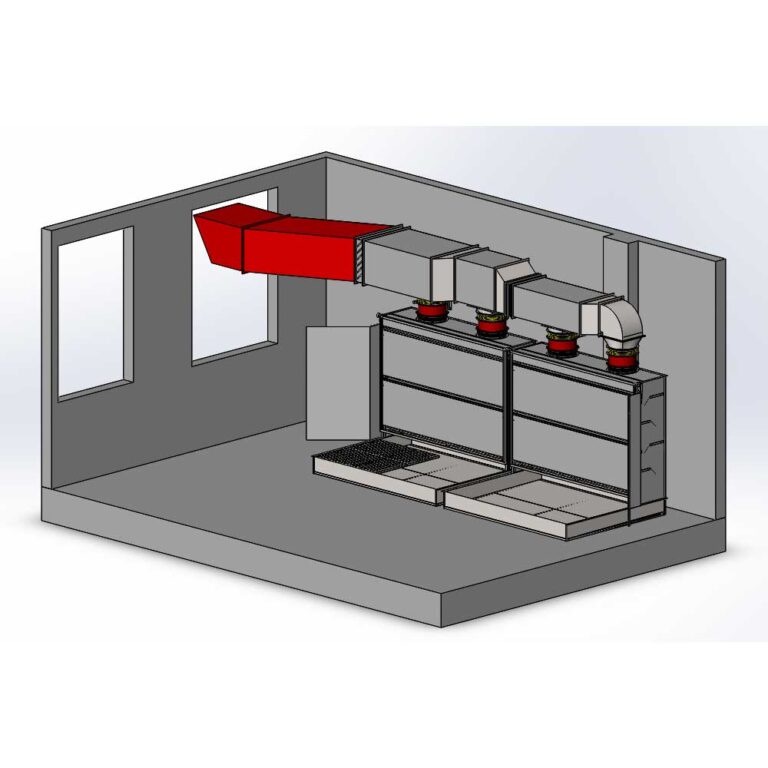

We operate two factories spanning 1,600 m², equipped with advanced machines and dedicated teams. Our design, engineering, and administration units work closely with clients to turn concepts into clear, buildable designs.